Crane systems can be quite complicated, and every part is crucial to the efficiency of the system as a whole. One of the most important parts of a crane is the reeving system, which affects elements like lifting capacity, overhead space, lift speed, and lateral movement. So, what is crane reeving?

What Is Crane Reeving?

Crane reeving is the configuration of the wire rope that lifts the hoist, including the drum, blocks, and pulleys. The type of reeving system will impact aspects like lift speed, headroom, and capacity of the crane. It also determines whether the crane system has any lateral movement or if it has true vertical lift.

Types of Reeving Systems

There are many different types of crane reeving systems, but they can all be described using three basic terms:

· Single – One wire rope comes off the drum.

· Double – Two wire ropes come off the same drum.

· Part – Number of ropes (lines) supporting the hook or load block.

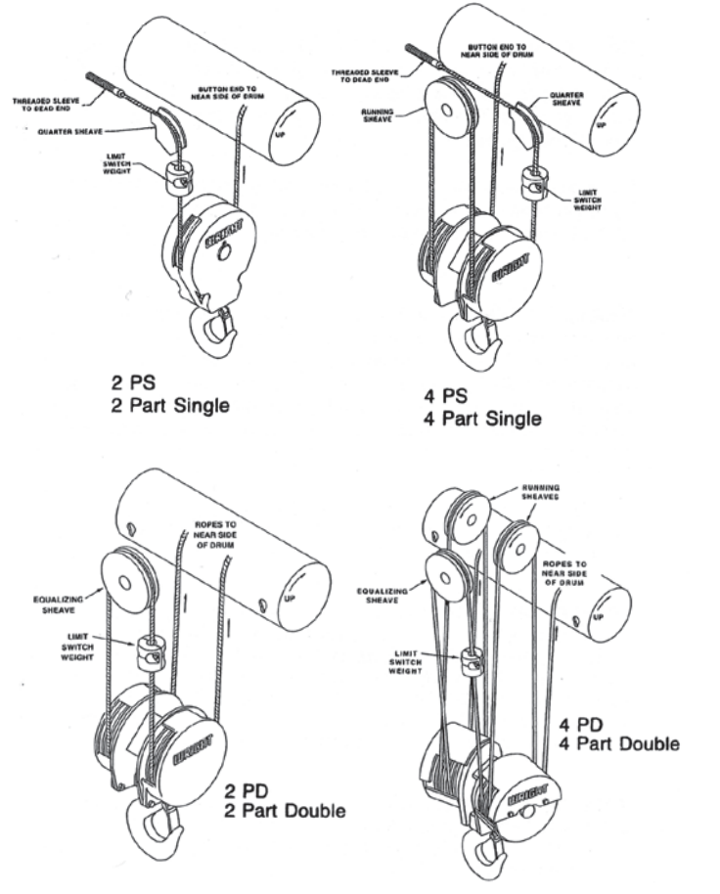

Diagram from the Acco Wright Speedway Crane Catalog

For example, a crane system with one wire rope coming off the drum, going through a pulley at the hook, and going into an anchor point is considered a two-part single reeving system (2PS). It has one wire rope coming off the drum (single) that’s distributed over two lines (parts).

Another aspect to consider is lateral movement. When a crane system is lifting or lowering a load, the wire rope is either spooled or released, adding or removing coils on the drum. As coils are added or released, it moves the hook or load block back and forth on the drum. This is lateral movement.

Some crane applications require precision lifting with no lateral movement. In these cases, a double-reeved system is best. Because the wire rope is lowered from two points that meet in the center, the load will never have lateral movement.

How to Calculate the Max Load of a Crane’s Reeving System

Each part adds to the mechanical advantage of the crane system, allowing it to better distribute the weight. For example, a two-part crane reeving system will have twice the mechanical advantage and capacity of a single reeving system—as long as all other aspects remain the same.

While adding more parts to a crane system will increase capacity, it’ll also decrease lift speeds, since there are more lines working at once. A two-part system will have twice the capacity of a one-part system, but the lift or lowering speed will be reduced by half.

Of course, it’s impossible to determine a crane’s lifting capacity based on the reeving system alone. There are many factors that impact lifting ability:

· Type and thickness of wire rope

· Size and material of the hoist drum

· Type and material of the block

· Whether the crane is mobile or static

· Materials used for sheaves

If you’re not sure of your crane’s lifting capacity, it’s always best to get a safety inspection from a certified professional. Working around cranes can be dangerous, so you definitely want to make sure you’re not overloading your equipment and potentially putting everyone around you in harm’s way.

Create a Safe and Efficient Work Environment

Understanding how a crane’s reeving system works is essential to maintaining a safe and efficient work environment. The wire rope reeving system impacts everything from lift capacity and speed to lateral movement and weight distribution. It’s one of the most essential parts of any crane system.

Ready to maximize safety on the job site? From installations and repairs to safety inspections and operator training, Crane Tech offers all the services you need to ensure a safe work environment and meet all OSHA regulations. Contact us today for a free consultation on all your crane-related needs.