Bridge cranes and gantry cranes are similar in both design and function. Both types of overhead cranes are designed to perform repetitive hoisting actions, in warehouses and heavy manufacturing factory floors.

Bridge and gantry cranes are extremely strong in design, and do not depend on cantilever leverage, but rather the strength of a winding cable or chain. Bridge and gantry cranes typically include a trolly system, from which a pneumatic or electric hoist is hung.

Here we will discuss bridge and gantry crane design in more detail, including where the machines commonly used. We will discuss the pros and cons of each design, and why each design is still in use today despite using centuries old technology.

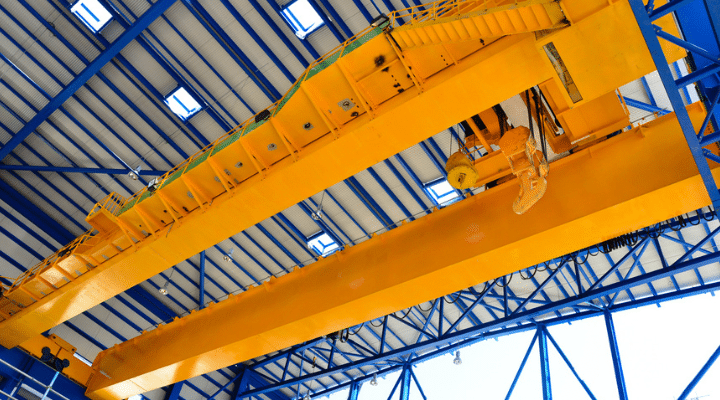

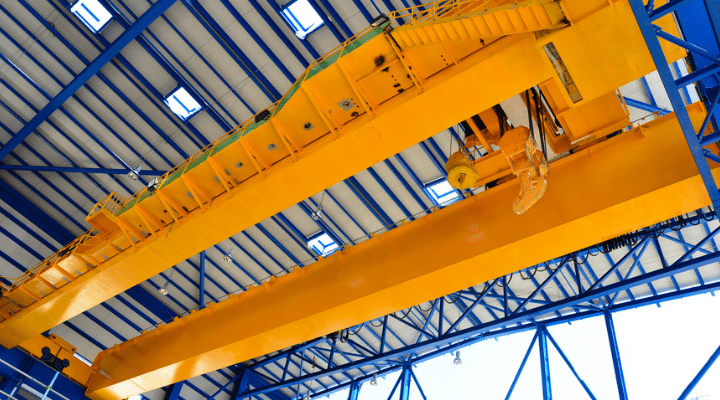

Bridge Cranes

Bridge cranes use two, parallel, horizontal rails, called runways, which are connected at the top of the crane. As the name implies, the bridge (the beam connecting the parallel runways together at the top), rides along the two runways, and spans over the object to be lifted.

In most designs a moveable trolley rides along the bridge, providing movement in all directions, including up and down. Bridge cranes are considered among the strongest crane designs because they use two rails, instead of just one.

However, bridge cranes are not generally portable because the rails are supported by permanently mounted vertical beams (aka, columns) for strength. The permanent mounting also allows for additional bracing and stronger material to material connections.

This design provides the hoist and trolly with the ability to move forward, backward, and side to side. In a gantry design this would require moving the entire crane to the object, which can be inefficient. Only the bridge and trolley need to move in a bridge crane design, making it a more efficient process.

Bridge cranes are perfect for moving very heavy objects along a predetermined path over and over. However, they are not as versatile as a gantry crane, since they generally require permanent installation.

What are the Pros of a Bridge Crane?

- Superior at moving objects across a wide and/or long work area

- Heavy duty capacity

- Omni-directional movement

- Can be sized as needed

What are the Cons of a Bridge Crane?

- Bridge cranes have more moving parts than a gantry or jib crane, so they generally require more maintenance

- Bridge cranes are generally more expensive to both purchase and own than a gantry crane.

Gantry Cranes

Gantry cranes are typically the simplest type of overhead crane design and are also the easiest to maintain. Gantry cranes are great for transporting a heavy object over a long distance because they can be mounted to a track, or simply roll around on casters.

A gantry crane on casters has no need for a track or predetermined path, if the floor is flat and level. However, this limits the lifting capacity of a gantry crane, as the contact points on the casters bear the weight of the entire load, creating a weak spot.

Gantry cranes are ideal for a factory floor or warehouse. Smaller duty gantry cranes often include heavy duty casters, while heavy duty versions typically ride along a track like a bridge crane.

Gantry cranes have a very high strength to weight ratio, which means the crane can lift many times its own weight, making it possible to move around. Typically, a gantry crane will have two vertical support beams, called columns, which are completely vertical. Spanning across these two columns is a beam called a girder, to which the hoist and trolly are attached.

A gantry crane looks much like a gallows, with the noose being replaced with a hoist. A hoist is hung from a trolley, which rides along, side-to-side, on the girder. Both gantry and bridge cranes can employ a top, or bottom, mounted trolley, which has both pros and cons, which we will discuss next.

Gantry cranes are very versatile and cost effective, so you will find them in virtually every manufacturing facility, especially smaller ones.

What are the Pros of a Gantry Crane?

- Very strong and durable.

- Relatively low cost

- Requires very simple maintenance

- Can be permanently mounted, follow a track, or ride freely on casters.

What are the Cons of a Gantry Crane?

- The only real downside to a gantry crane is the limited lifting capacity, as compared to a bridge style crane. Although a bridge crane is often double the size of a gantry crane, it can also provide double the lifting power.

Can Gantry Cranes and Bridge Cranes Use Top-Running, or Under-Running Trolleys?

Top running trolleys ride on top of the girder, so the trolley wheels simply push down against the girder. Under-running trolleys also ride along the girder but hang from wheels riding inside a track mounted to the underside of the girder, much like a sliding closet door.

Both gantry and bridge cranes can use a top running, or under running trolley. On top running trolleys, the trolley sits atop the girder, so all the forces are directed straight down through the columns.

Under-running trolleys hang from underneath, so these forces are transferred to wheels that ride along a track. Just as it is easier to push something than to pull it, in this design, the weight of the object pulls down on the trolley, limiting its lifting capacity to the strength of the hook, cable, or chain.

Top running cranes can endure heavy lifting, but the mechanism requires a fair amount of space above the crane. This design is great for large facilities with lots of space and provides the hoist with the most direct lifting support.

Under-running trolleys reduce the headroom required for the crane, which can be very handy in a space with low ceilings. However, this smaller space is created at the expense of lifting capacity, which is why both designs are commonly used. Either can be ideal, depending on the space the crane will occupy and the job it is to perform.

Need help with your next crane project?

Selecting the best type of crane for your facility often requires a professional with the training and experience you need. Get a quote here and speak to a licensed crane technician today.