Overhead crane design has evolved over the last hundred years to include a variety of sizes, applications, and general uses. Overhead cranes are the most common type of industrial crane design, and are invaluable in manufacturing, material handling, and storage applications.

Here we will discuss the most common types of overhead cranes used in modern manufacturing. For clarity, we’ll omit overhead cranes used in building construction, such as a tower crane, and focus on the seven most common overhead crane designs used in manufacturing.

1. Gantry Cranes

Gantry cranes are considered one of the most versatile types of overhead crane design and are used to transport objects along a flat, level surface. Some gantry cranes ride along a track, while smaller versions often use heavy duty castors instead, for additional maneuverability.

Gantry cranes are very simple in design and are often built from I-beams for a high strength to weight ratio. Typically, a gantry crane will have two vertical support beams, called columns, with a beam spanning across the top, connecting the two vertical columns. A hoist is hung from the top beam (known as a girder) and is usually connected to a trolley.

The trolley rides along the girder and moves the object from side to side, while the entire crane travels along a runway beam to move the object forward or backward.

Where are Gantry Cranes Used?

Gantry cranes are typically found in factories, shipping yards, container yards, and manufacturing facilities, due to their robust design and inherent lifting strength. Gantry cranes are very common in ship building, car manufacturing, and other work where a high weight capacity is required.

What are the Advantages of a Gantry Crane?

- Very strong

- Simple operation and design

- Can be permanently mounted, or portable

What are the Disadvantages of a Gantry Crane?

- Generally, requires a flat, even surface, as opposed to a jib crane, which does not.

2. Jib Cranes

Jib cranes are perhaps the most used type of crane design, as they can be configured to take up a smaller footprint than a gantry crane. Instead of vertical support on both sides like a gantry crane, jib cranes only have one vertical beam, known as a column.

The horizontal beam, called a boom, extends out from the column at a 90-degree angle. A trolley rides along the boom from end to end and can pivot up to 360 degrees on its axis.

Jib cranes can also be wall mounted, which frees up the space the column would normally use on the factory floor. Jib cranes don’t usually travel around like a gantry crane, but simply pivot in place. This design limits the application of a jib crane but makes it ideal for transporting objects short distances safely and quickly.

What are the Advantages of a Jib Crane?

- Excellent for moving objects short distances very efficiently

- Can employ electric, or manual, hoists

- Can be wall mounted, saving floor space

- Can be permanently installed, or portable

What are the Disadvantages of a Jib Crane?

- Jib cranes don’t have the same lifting power as a comparably sized gantry crane because they are only supported on one side.

3. Bridge Cranes (aka Overhead Crane)

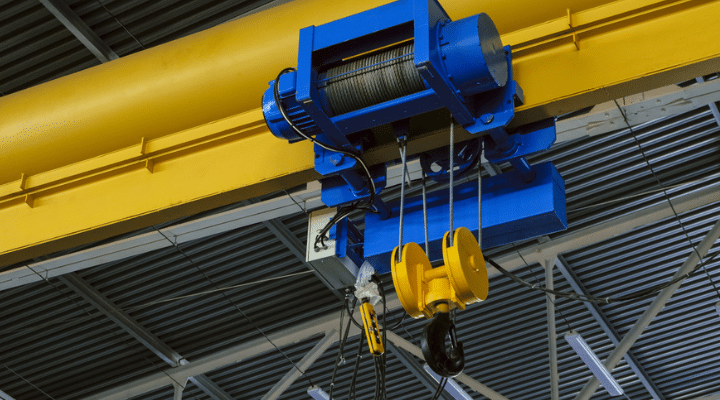

Bridge cranes are extremely strong. Most use two parallel, horizontal rails, called runways. The bridge (a beam (or girder) between the parallel runways), rides perpendicularly along the two runways. A hoist hanging from a trolley travels along the bridge, giving the crane movement in all directions, including up and down.

Bridge cranes are not generally portable, as the rails are supported by permanent vertical beams (or columns) in most cases. However, this design allows for the hoist and trolley to move forward, backward, and side to side, which allows for a nearly endless list of applications.

What are the Advantages of a Bridge Crane?

- Superior at moving objects across a wide and/or long work area

- Heavy duty capacity

- Omni-directional movement

- Can be sized as needed

What are the Disadvantages of a Bridge Crane?

- Bridge cranes have more moving parts than a gantry or jib crane, so they generally require more maintenance

4. Workstation Cranes

Workstation cranes are just what the name implies. Many use a jib configuration, but all are designed for a specific task. These cranes are used at a single workstation, instead of moving around from place to place. These cranes are usually light duty, and generally smaller than gantry or bridge cranes.

Workstation cranes are common in automotive manufacturing, and other factories where some jobs require more intricacy and maneuverability. Workstation cranes are often computer controlled, as the tasks it performs require precision.

What are the Advantages of a Workstation Crane?

- Designed for a specific task, so quality and ease of use is excellent

- Reduces worker fatigue

- Allows for very precise work

- Great for repetitive tasks

What are the Disadvantages of a Workstation Crane?

• Since they are purpose built, workstation cranes are not very versatile outside the job they were designed for

5. Monorail Cranes

Monorail cranes are very simple in design and function. Monorail cranes are similar to a gantry crane, in that they follow a specific path. Monorail cranes are fantastic for moving objects from point A to point B, as long as the path between them is in line. Monorail cranes follow a precise path, with no movement from side to side.

This feature makes monorail cranes popular in factories and other assembly lines that follow a single path and do the same thing over and over. Monorail cranes can turn in directions in a curve shape, but they do not move in a directly perpendicular direction. Monorail cranes work just like a monorail at a theme park, following the same path over and over.

What are the Advantages of a Monorail Crane?

- Excellent for moving objects along a single path

- Cost effective and simple to maintain

- Great for warehouses and other structures with straight aisles

What are the Disadvantages of a Monorail Crane?

• Not versatile or moveable

6. Top-Running Cranes

Gantry and bridge cranes can employ either a top running, or under running design. In both designs the horizontal rail (aka runway) connects to two vertical beams, (aka columns), one on either side. Top running cranes ride on top of the runway, as opposed to hanging from it.

Top running cranes transfer the force through the columns down to the floor, eliminating weak points, such as a mechanical connection. In contrast, under running cranes hang from below the runway. This design requires a mechanical connection to the runway, which is a weak point.

What are the Advantages of a Top Running Crane?

- Very safe, as the design is less reliant on mechanical connections to the runway

- Can move materials in virtually any direction

- Generally considered the strongest, if not the smallest, crane design

What are the Disadvantages of a Top Running Crane?

• Because the rails sit on top of the runway, instead of hanging from it, they require more headroom. This makes them less appropriate for shorter buildings

7. Under-Running Cranes

Under running cranes have the bridge underneath the runways, instead of on top. This design reduces the headroom required for the crane, but also shortens its vertical reach. Under running cranes are great for structures with low ceiling headroom and limited floor space.

What are the Advantages of an Under Running Crane?

- More appropriate for buildings with shorter walls, increasing the reach of the crane

- Perfect for moving large objects short distances when space is limited

What are the Disadvantages of an Under Running Crane?

- Because the forces are pulling from underneath, as opposed to pushing down from above on the columns, the lifting capacity is often lower than a similar top running type crane.

Need help with your next crane project?

Selecting the best type of crane for your facility requires professional help. Get a quote here and speak to a licensed crane technician today.